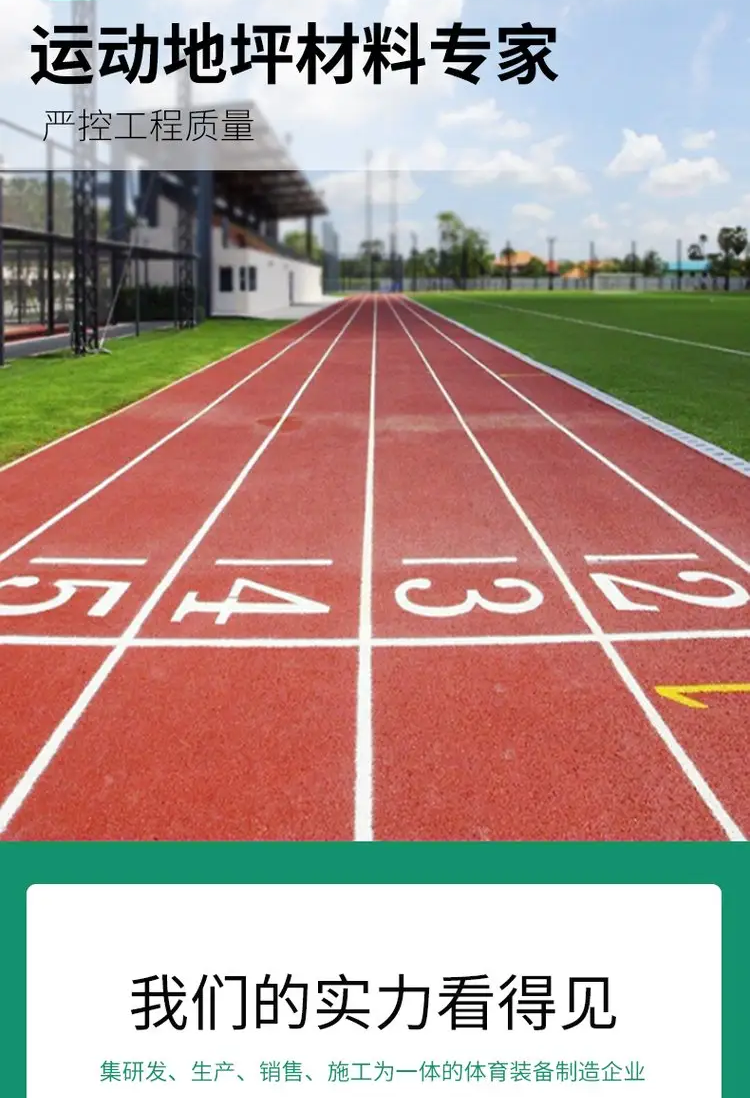

Hybrid self-textured plastic track

Why choose us?

As a professional contractor for sports venue facility projects, the company provides users with "one-stop" services from engineering design consultation to raw material production to engineering construction.

Ask a Question About This Product

- Stock: In Stock

- Brand: 南方體育工程

- Model: NFTY-001

- SKU: 平方米

Product Specifications

| Plastic track Specifications | |

| Applicable Scenarios | Primary and secondary schools, kindergartens |

| Material manufacturer | Zhongshan South Sports Facilities Engineering Co., Ltd |

| Origin | Guangdong, China |

| Product Name | Hybrid plastic track |

| Thickness | 13 MM |

产品介绍

The hybrid plastic track is a track material with a mixed structure. The surface layer is PU particles or EPDM weather-resistant environmentally friendly colored particles. The matrix is full PU mixed with some rubber particles. The construction process is simple and meets international competition standards. The standard thickness is 13mm.

Characteristics of the hybrid plastic track: It can be used all day and night, and can maintain a high level of quality in any season and temperature difference. It can be used immediately after rain to increase the utilization time and improve the utilization rate of the venue.

Elasticity: It has moderate elasticity and rebound force, which can reduce physical consumption and improve competition results.

Impact resistance: It can moderately absorb the impact of the foot, reduce sports injuries, and is suitable for long-term practice and competition.

Weather resistance: It will not fade, powder or soften due to pollution from ultraviolet rays, ozone, and acid rain, and can maintain its bright colors for a long time.

Wear resistance: The wear resistance is less than 2.5%, which meets the needs of long-term and high-frequency use of schools at all levels.

Compression resistance: It will not be unable to restore elasticity due to the heavy pressure of track and field equipment.

Nail resistance: Even at the 100-meter starting point where the force is the greatest and the most frequently used, it will not be damaged by spikes or starting blocks.

Impact resistance: It has a strong elastic layer and a buffer layer, which can absorb strong impacts without damaging the surface.

Flatness: Self-leveling materials are used during construction, and the surface is flat, which can meet the requirements of a particularly flat competition venue.

Adhesion: Special construction treatment, strong adhesion, can suppress the rise of moisture, no bubbling, peeling and other phenomena.

Safety: It can prevent sports injuries caused by falls.

Economic: Easy maintenance and save management costs.

Color: Special high-elastic EPDM and PU particles, soft surface color, granular surface, prevent the reflection of dazzling light, beautiful and durable, and can be matched with multiple colors.

Construction technical indicators

Report

Editor

Specific gravity: ±0.10

Hardness (HS): 45~65

Tensile strength (kgf/c㎡ (Mpa): 25 (2.45) or more

Tear strength (kgf/cm(N/mm): 10 (98) or more

Elongation: 250 or more

Compression set: 35 or more

Abrasion resistance: 2.5 or less

Hardness (HS): Change of original hardness value: ±5

Tensile strength (kgf/c㎡ (Mpa): 80%~150% of the quantity before aging test

Tear strength (kgf/cm(N/mm): 80%~150% of the quantity before aging test

Elongation: 200 and above

Paving process description

Report

Editor

Plastic track paving

The construction process is to use a three-step construction method for paving. First, add an appropriate amount of rubber particles to the glue liquid, spread the base glue to a thickness of 8 mm, wait for it to solidify, and then spread the glue liquid with a thickness of 2 mm on it, and evenly sprinkle red particles manually, recycle the excess rubber particles, and finally spray a layer of glue liquid on it.

Process diagram

Cleaning the site → Base glue ingredients → Mixing and stirring → Spreading → Defoaming → Solidification → Top glue ingredients → Mixing and stirring → Spreading → Defoaming → Sprinkling particles → Recycling rubber particles → Rolling glue → Measuring and drawing lines → Checking points and lines → Completion

Paving process description

Report

Editor

(1) First check the flatness of the base layer and level the concave and convex parts (such as cement concrete foundation requires acid washing).

(2) Laying the base glue: Before laying the base glue, clean the foundation and prepare the construction tools.

a) Measure the position of the construction line according to the process requirements and place the construction line.

b) Start from one side of the field and apply glue at one time according to the width of the field.

c) Apply glue at a uniform speed and promptly fill or smooth the exposed bottom, concave and convex areas.

d) After the glue is formed, check the entire field to ensure the thickness of the surface glue.

(3) Spreading of the surface glue:

a) When applying glue, try to shorten the interval between each bucket of glue to ensure a uniform glue forming speed.

b) Always observe the thickness of the glue surface.

c) When applying the surface glue, sprinkle red particles before the surface glue is cured. After it is completely cured, clean up the excess surface glue particles.

d) Spray glue to ensure that the particles do not fall off.

(4) Spraying of process lines:

According to the current standards for track and field facilities, accurately measure the position of the process lines and then spray them with polyurethane paint.